How is the radiotherapy positioning film manufactured?

Radiotherapy positioning films are one of the most widely used positional fixation tools in tumor radiotherapy, and they are mainly made of polycaprolactone . Maidfir m, as a manufacturer with long-term expertise in positioning films, will reveal the production process of positioning films for the first time, sharing every step from raw materials to finished product shipment, allowing distributors to understand how a positioning film is made.

1: From granular raw materials to boards

The factory randomly samples and tests the raw material polycaprolactone. Only after passing the tests can it be mixed with other materials and extruded into large-size sheets. Polycaprolactone has high crystallinity and low melting point. It can be freely stretched after being fully immersed in a constant temperature water bath at 65-70 ℃

for three minutes, and then cooled and shaped after 15-20 minutes. These properties perfectly meet the fixation needs of radiotherapy patients. Since its application in radiotherapy decades ago, this material has received widespread praise from industry professionals for its irreplaceable positioning and fixation effect . At the same time, polycaprolactone is environmentally friendly. In soil and aquatic environments, it can completely decompose into carbon dioxide and water within 6-12 months without polluting the environment.

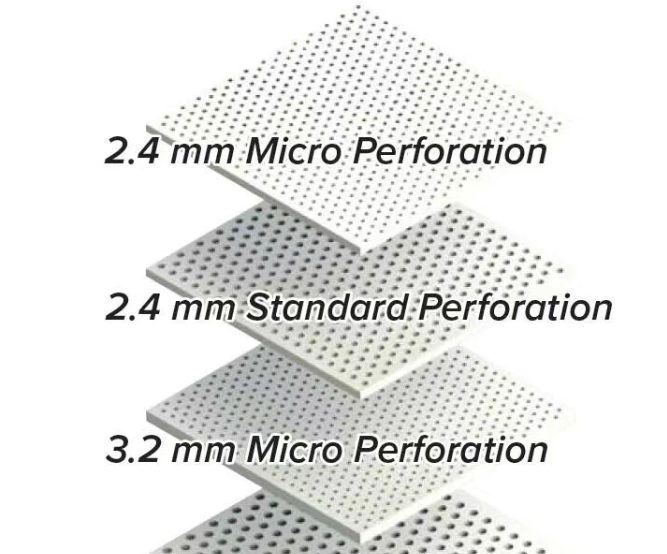

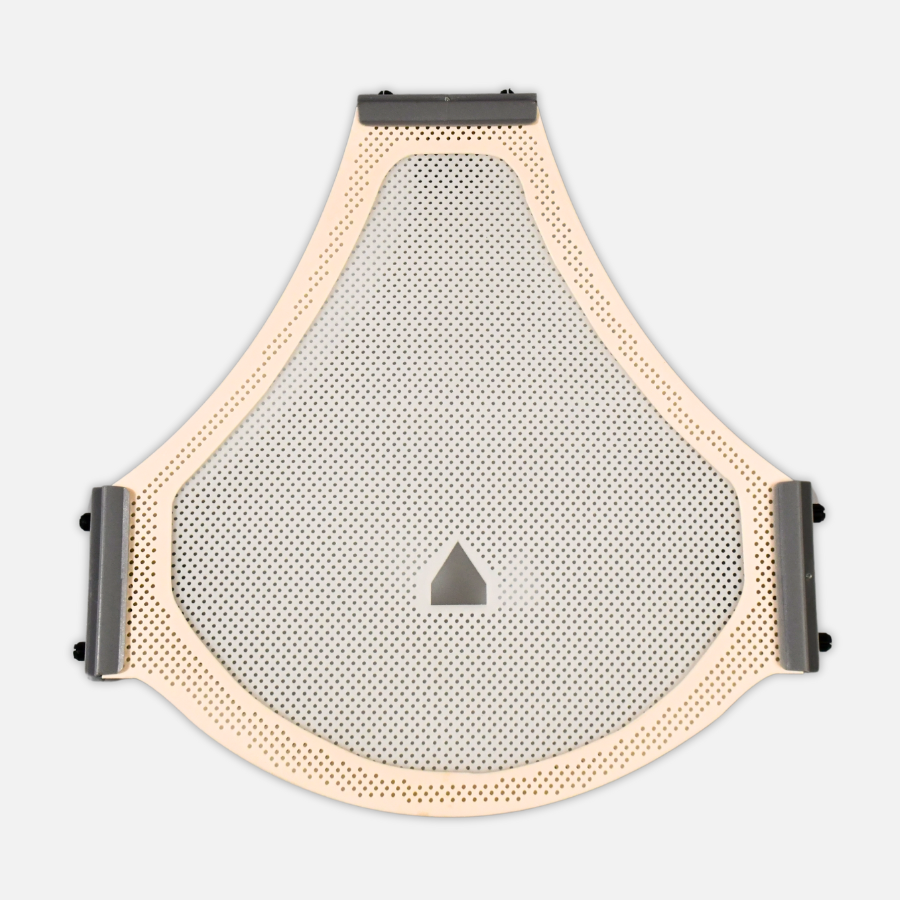

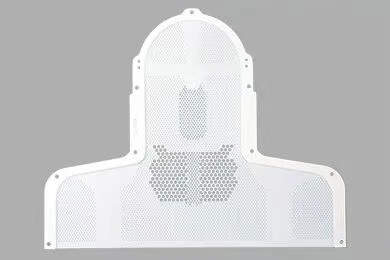

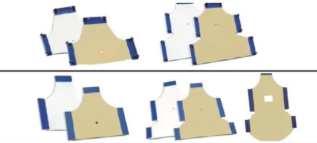

2: punching and cutting

Large-size membranes are typically available in thicknesses of 2.4 or 3.2 mm ( Maidfirm offers a special 4.0 mm thickness), and are perforated according to clinical needs. Commonly, they feature a 36% uniform mesh, but 12%, 22% , and 42% meshes are also available , as well as non-porous membranes (often used in proton and heavy ion therapy). More specialized intensity-modulated membranes and fenestrated (perforated) membranes are also available. After perforation, the membranes are cut according to the treatment area, primarily the head, head and neck, cervical and thoracic region, and abdomen. Maidfirm ‘s positioning membranes undergo a secondary edge finishing process to ensure the edges do not “cut” the patient during treatment. Finally, each positioning membrane is carefully inspected to ensure a smooth, clean surface free of burrs and rough edges.

3: coating and irradiation

After the positioning membrane is perforated, cut, and shaped, it’s time for each manufacturer to showcase their true capabilities: coating and irradiation. This is the final step in determining the final product characteristics of the positioning membrane . Based on their experience and desired clinical efficacy, each manufacturer will formulate different coating recipes to enhance other membrane properties, such as antibacterial and anti-stick properties. All Maidfirm positioning membranes are coated with both antibacterial and anti-stick coatings . After uniform coating and drying, the irradiation process begins. The amount of irradiation dose is related to tensile stiffness and shrinkage rate. Too high a dose results in a high shrinkage rate, while too low a dose can cause the membrane to break. Clinically, radiation therapists and patients are most likely to notice the stiffness and shrinkage of the positioning membrane; therefore, this step is particularly important, requiring accurate irradiation doses for each batch of membranes .

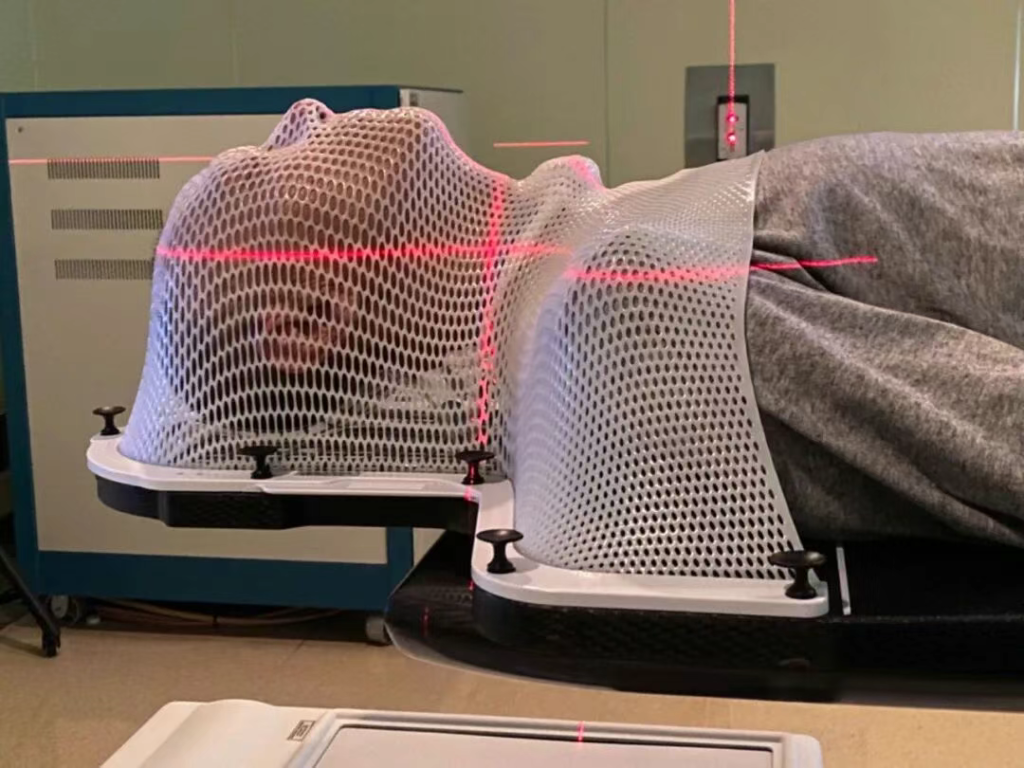

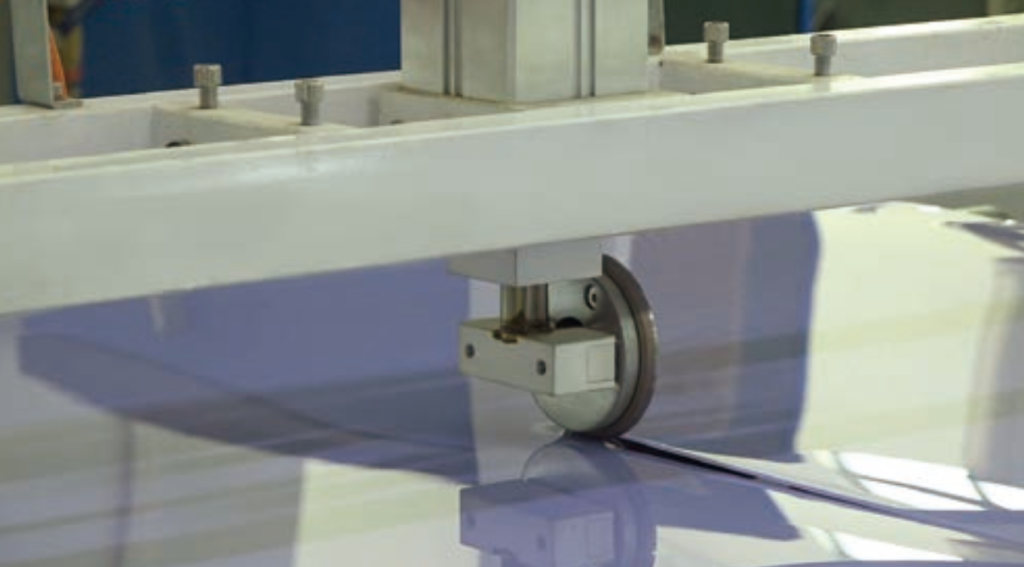

4: Welding the frame

welding of the film and frame is required . Over the decades of positioning film development, different manufacturers have designed various frame types, the most common being the American S-type and the European L-type. After the frame passes inspection, it is welded in sections using a welding process. Compared to traditional hot-melt and adhesive methods, ultrasonic welding is faster, stronger, and allows for real-time monitoring of all welding parameters, maximizing control and preventing frame detachment.

5: Packaging

The final step is packaging and shipping. Before sealing the box, each film is checked for scratches and damage, and every accessory is installed in place. The packaging is ensured to be tightly sealed, and an inspection report and instruction manual are included with the box .

6: Conclusion

The above is just a general overview of the positioning membrane production process; more details are not shown here. If you are interested in purchasing our products, please fill out the form on this website or our official website (maidfirm.com/sales@maidfirm.com) for inquiries.

Maidfirm strictly controls the production process, conducting random sampling inspections after each production stage to ensure high-quality shipments of every batch. Furthermore, samples of each batch of Maidfirm positioning membranes are retained to ensure prompt response to customer and hospital department needs, facilitating personalized adjustments.

Finally, for international customers, Maidfirm offers free trials of radiotherapy positioning membranes ; please contact us anytime if needed.