Top 5 Factors to Consider When Choosing Thermoplastic Materials for Splinting and Radiotherapy

Introduction

In the world of rehabilitation and radiation oncology, the precision of a splint or the stability of a mask can directly impact patient outcomes. For years, clinicians have relied on high-end brands, often at a premium cost. But as healthcare facilities look for more sustainable procurement options, the question arises: How do you choose a high-performance thermoplastic material without overpaying?

In this guide, we break down the critical performance factors every therapist and purchasing manager should know.

- 100% Memory and Re-moldability

One of the hallmarks of premium thermoplastic sheets is elastic memory. A high-quality material like those developed at Maidfirm should return to its original shape when reheated.

- Why it matters: This allows for multiple adjustments if the initial molding isn’t perfect, reducing material waste and saving clinic time.

- Benchmark: Maidfirm materials are engineered to match the 100% memory standards of global market leaders.

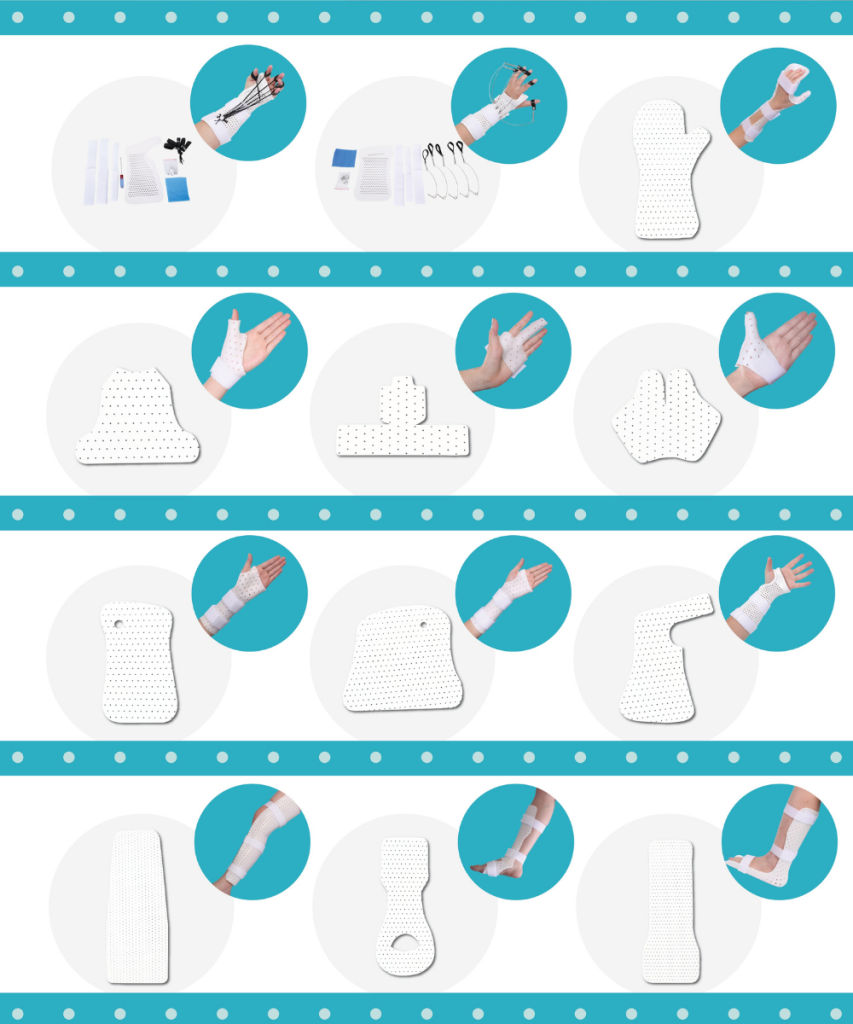

- Drapability vs. Control (Handling Characteristics)

Different clinical applications require different handling styles.

- High Drapability: Best for complex contours like finger splints or facial masks where gravity helps the material conform to the patient.

- High Resistance to Stretch: Better for larger orthoses (like ankle or back splints) where the therapist needs more control.

- Maidfirm Solution: We offer a range of series—from highly conformable lite sheets to rigid max-strength sheets—to suit every clinical preference.

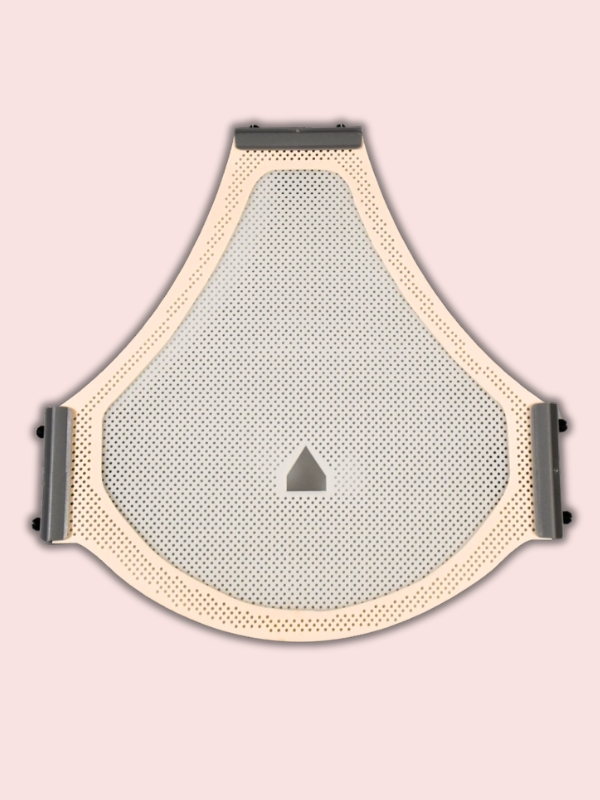

- The “Shrinkage” Factor in Radiotherapy Masks

For radiation therapists, shrinkage is the enemy of precision. If a mask shrinks too much after cooling, it causes patient discomfort and sub-millimeter inaccuracies in dose delivery.

- The Science: Maidfirm’s RT masks are made from high-grade PCL with specialized additives that limit shrinkage to a minimum.

- Compatibility: Our frames are designed to be 100% compatible with Varian, Elekta, and Siemens baseplates.

- Skin Safety and Biocompatibility

Since these materials stay in direct contact with the patient’s skin—sometimes for hours or across weeks of treatment—safety is non-negotiable.

- Check for: HTW(Biocompatibility) and CE Marking.

- Avoid: Low-cost materials that use industrial-grade PCL, which can cause skin irritation or unpleasant odors when heated in a water bath.

- The Source Factory Advantage: Quality vs. Cost

Why pay a 300% markup for a brand name? As a direct manufacturer, Maidfirm provides clinical-grade materials at factory prices. By cutting out the multiple layers of international distributors, hospitals can reallocate their budget toward other patient care needs without sacrificing the quality of their consumables.

Conclusion: Ready to Benchmark Maidfirm?

Transitioning to a new material is a big decision for any clinic. That’s why we let our quality speak for itself.